PFAS Free Solution:

PolySilAl-D Flame Retardant

PSAD

Environmentally

Friendly

Halogen and PFAS free, release no harmful substances during combustion

effective

retardant

Incorporation of polysiloxane micropowder, aluminum hydroxide, and DOPO enhances flame retardancy

material

safety

Excellent thermal stability and char-forming ability, significantly enhancing material safety

sustainable

Production

PSAD is suitable for large-scale production due to simple and cost-effective preparation method

structure

PSAD is a composite flame retardant consisting of polysiloxane micropowder, aluminum hydroxide, and phosphorus-based flame retardant (DOPO). PSAD takes advantage of the char-forming ability of polysiloxane micropowder, as well as aluminum hydroxide releasing water vapor during combustion, and DOPO inhibiting free radical chain reactions to achieve a synergistic flame-retardant effect.

PSAD包含三种主要成分:聚硅氧烷微粉(Polysiloxane Micropowder), 氢氧化铝(Aluminum Hydroxide)和磷系阻燃剂(DOPO)。PSAD 利用聚硅氧烷微粉的成炭能力,以及氢氧化铝在燃烧过程中释放水蒸气和 DOPO 抑制自由基连锁反应的作用,实现协同阻燃效果。

Flame Retardant Mechanism

The Role of Polysiloxane Micropowder:

- At high temperatures, it forms a Si-O-Si network structure, promoting char formation and impeding the transfer of heat and oxygen, thereby enhancing the flame retardancy of the material.

The Role of Aluminum Hydroxide:

- In combusiton, it decomposes and releases water vapor, diluting the combustible gases generated during burning. Simultaneously, it absorbs a significant amount of heat, reducing the surface temperature of the material and retarding the combustion process.

The Role of DOPO:

- Through its synergistic action in both the gas phase and the condensed phase, it inhibits the free radical chain reactions occurring during combustion, facilitating char formation and improving the flame retardancy of the material.

More about PolySilAl-D Flame Retardant

PSAD flame retardant exhibits excellent eco-friendly properties. The flame retardants used are free from PFAS and halogens, causing no environmental pollution; minimal smoke and toxic gases are generated during combustion, resulting in low smoke and toxicity; and since the PCR-PTFE material itself is a post-consumer recycled material, the use of the PSAD flame retardant aligns with the principles of circular economy and sustainable development.

PSAD阻燃剂具有出色的环保特性。它所使用的阻燃剂不含有氟和卤素,对环境无污染;在燃烧过程中产生的烟雾和有毒气体极少,属于低烟低毒类型;而且由于PCR-PTFE材料本身是消费后回收材料,因此PSAD阻燃剂的使用符合循环经济和可持续发展的要求。

PSAD flame retardant is highly suitable for applications requiring high flame retardancy. In the electronics field, it can be used for manufacturing enclosure materials; in the automotive industry, it can be applied to produce interior parts and components, providing enhanced safety; in the building materials sector, it can be utilized for the production of fire doors, fire-resistant boards, and other construction materials, improving fire resistance.

PSAD阻燃剂非常适合应用于各种需要高阻燃性能的领域。在电子电器领域,它可用于制造外壳材料;在汽车行业,可用于生产内饰和零部件,提供更高的安全性;在建筑材料方面,可用于防火门、防火板等建材的生产,提高防火性能。

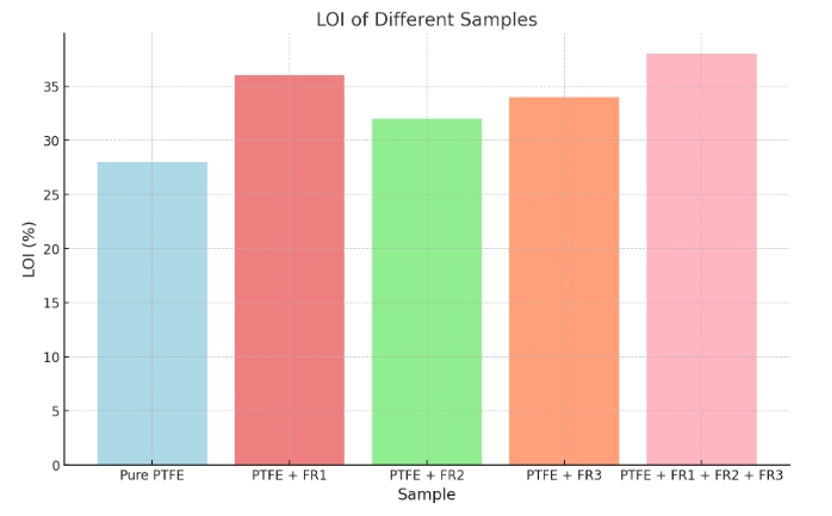

Experiment Data: LOI Test

LOI Test Results:

| Samples | LOI(%) |

|---|---|

| Pure PCR-PTFE | 28 |

| PCR-PTFE + FR1 | 36 |

| PCR-PTFE + FR2 | 32 |

| PCR-PTFE + FR3 | 34 |

| PCR-PTFE + FR1 + FR2 + FR3 (PSAD) | 38 |

The addition of polysiloxane micropowder (FR1), aluminum hydroxide (FR2), and DOPO (FR3) significantly increases the limiting oxygen index (LOI) value of the PCR-PTFE material. The synergistic effect of these three flame retardants is optimal, resulting in an LOI value of 38%.

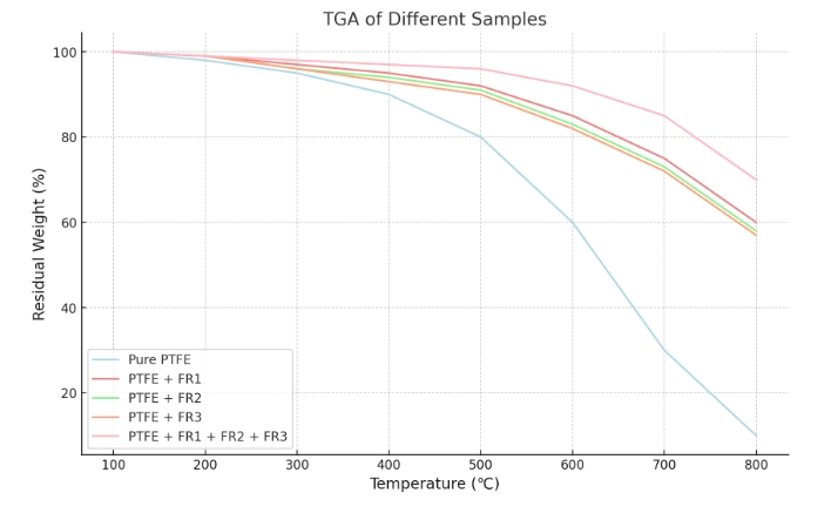

Experiment Data: TGA Test

TGA Test Results:

| Temperature (℃) |

Pure PTFE (wt%) | PTFE + FR1 (wt%) | PTFE + FR2 (wt%) | PTFE + FR3 (wt%) | PTFE + FR1 + FR2 + FR3 (PSAD) (wt%) |

| 100 | 100 | 100 | 100 | 100 | 100 |

| 200 | 98 | 99 | 99 | 99 | 99 |

| 300 | 95 | 97 | 96 | 96 | 98 |

| 400 | 90 | 95 | 94 | 93 | 97 |

| 500 | 80 | 92 | 91 | 90 | 96 |

| 600 | 60 | 85 | 83 | 82 | 92 |

| 700 | 30 | 75 | 73 | 72 | 85 |

| 800 | 10 | 60 | 58 | 57 | 70 |

After incorporating the flame retardants, the residual weight of the PCR-PTFE material at high temperatures significantly increases. Particularly at 800°C, the residual weight is enhanced from 10% for neat PTFE to 70% for PTFE with PSAD addition, indicating that PSAD effectively prevent the material from significant decomposition under high temperatures and improve the thermal stability of the material.

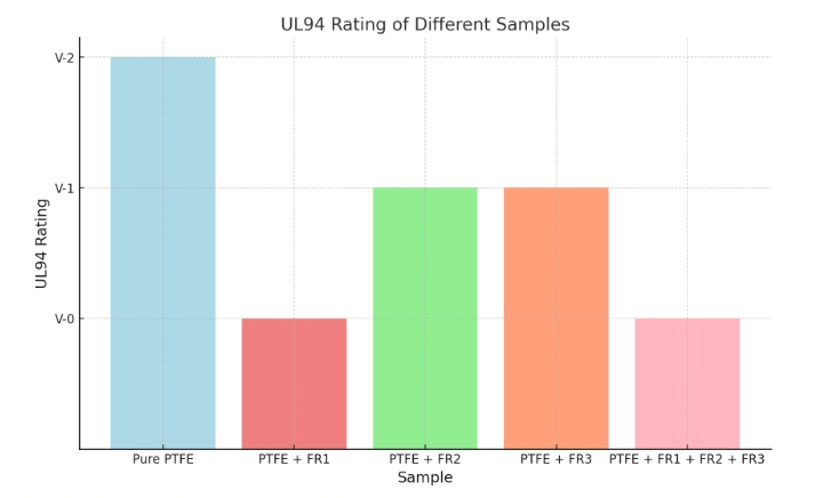

Experiment Data: UL94 Vertical Burn Test

UL94 Vertical Burn Test Results:

| Samples | Rating |

| Pure PTFE | V-2 |

| PTFE + FR1 | V-0 |

| PTFE + FR2 | V-1 |

| PTFE + FR3 | V-1 |

| PTFE + FR1 + FR2 + FR3 (PSAD) | V-0 |

The addition of polysiloxane micropowder (FR1) enables the PCR-PTFE material to achieve the UL94 V-0 rating. Aluminum hydroxide (FR2) and DOPO (FR3) individually achieve a V-1 rating. The synergistic effect of the PSAD is optimal, allowing the material to attain the UL94 V-0 rating.

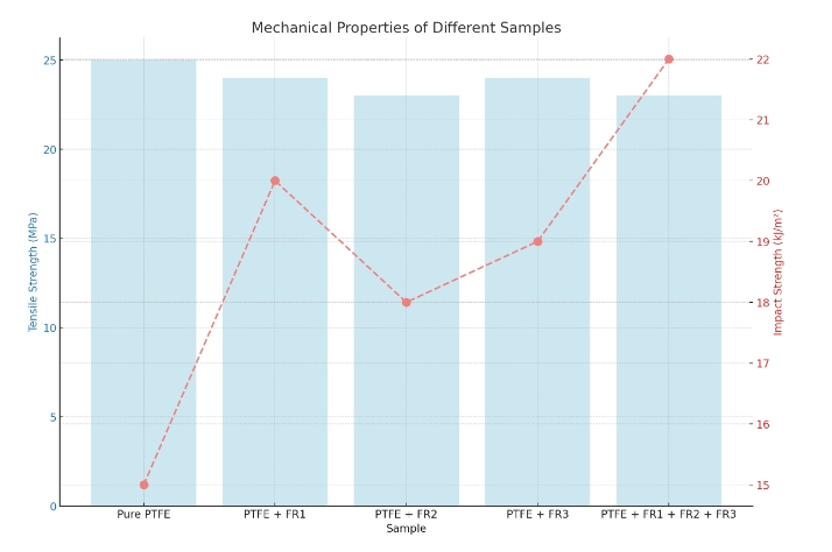

Experiment Data: Mechanical Properties Test

Mechanical Properties Test Results:

| Samples | Tensile Strength (MPa) | Impact Strength (kJ/m²) |

| Pure PTFE | 25 | 15 |

| PTFE + FR1 | 24 | 20 |

| PTFE + FR2 | 23 | 18 |

| PTFE + FR3 | 24 | 19 |

| PTFE + FR1 + FR2 + FR3 (PSAD) | 23 | 22 |