Halogen&PFAS Free Solution:

Phosphorus-Silicon Synergistic Flame Retardant

PSSR

Environmentally

Friendly

Halogen and PFAS free, release no harmful substances during combustion

effective

retardant

Incorporation of phosphorus-containing groups enhances flame retardancy

material

safety

Excellent thermal stability and char-forming ability, significantly enhancing material safety

sustainable

Production

PSSR is suitable for large-scale production due to simple and cost-effective preparation method

structure

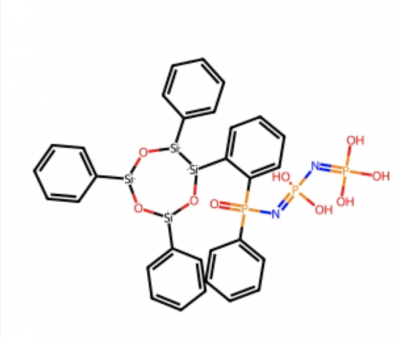

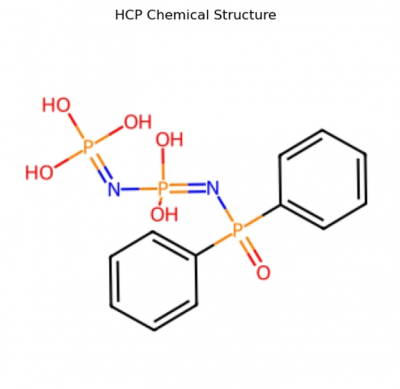

PSSR is a composite of phosphorus-containing groups and polyhedral oligomeric silsesquioxane (POSS) cages. The incorporation of phosphorus-containing groups enhances flame retardancy, while taking advantage of the thermal stability and char-forming ability of POSS to achieve a synergistic flame-retardant effect.

PSSR由磷基团和笼型硅倍半氧烷(POSS)复合而成,通过引入磷基团提升阻燃效率,利用POSS的热稳定性和成炭性,形成协同阻燃效果。

Flame Retardant Mechanism

The Role of Phosphorus-Containing Groups:

- During combustion, HCP decomposes to produce phosphoric acid and polyphosphoric acid, which can form a glassy protective layer covering the material surface, impeding heat and oxygen transfer, thereby suppressing combustion.

- The gases released during HCP decomposition (e.g., NH3) dilute the combustible gases in the burning zone, further inhibiting combustion.

The Role of POSS:

- The organic substituents of POSS absorb heat during decomposition, slowing down the degradation rate of the polymer.

- After POSS combustion, the formed silicon oxides deposit on the unburned polymer surface, creating a protective layer that prevents further combustion.

- POSS increases the char formation of the material, forming an insulating layer that effectively reduces heat transfer.

More about Phosphorus-Silicon Synergistic Flame Retardant

PSSR is a halogen-free and PFAS-free environmentally friendly flame retardant. The raw materials used in its preparation process and the reaction conditions are environmentally benign. The flame retardant material produced does not release harmful halides or fluorides during combustion, meeting the current high standards for environmental protection and safety.

PSSR完全不含卤素和氟元素,属于无氟无卤的环保型阻燃剂。其制备过程中使用的原料和反应条件对环境友好,生成的阻燃材料在燃烧时不会释放有害的卤化物或氟化物,符合当前对环保和安全的高标准要求。

Through the above design, PSSR not only exhibits high flame retardancy, but also possesses excellent thermal stability and char-forming ability, significantly enhancing the flame retardant rating and safety of the material.

通过以上设计,PSSR不仅具备高效的阻燃性能,还具有良好的热稳定性和成炭性能,能够显著提升材料的阻燃等级和安全性。

PSSR can be added to engineering plastics such as polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS) copolymers, etc. The recommended addition amount is 5-15% by mass. It is suitable for applications requiring high flame retardancy, such as electronic and electrical enclosures, automotive components, building materials, and other fields.

PSSR可被添加到聚碳酸酯(PC)、丙烯腈–丁二烯–苯乙烯(ABS)等工程塑料中,建议添加量为5-15%(质量分数)。 适用于电子、电器外壳、汽车部件、建筑材料等需要高阻燃性能的领域。

Experiment Data

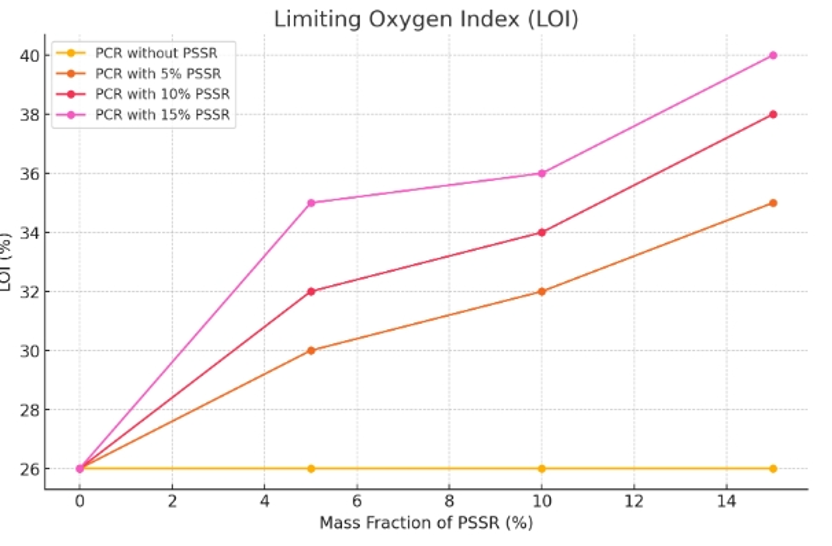

LOI Test Results:

| PSSR content (%) | 0 | 5 | 10 | 15 |

|---|---|---|---|---|

| LOI (%) | 22 | 28 | 31 | 35 |

The limiting oxygen index (LOI) value of PCR without PSSR addition is 22%, while after adding 5%, 10%, and 15% PSSR, the LOI values increase to 28%, 31%, and 35%, respectively. The results demonstrate that with increasing PSSR content, the flame retardancy of the material is significantly enhanced.

Experiment Data

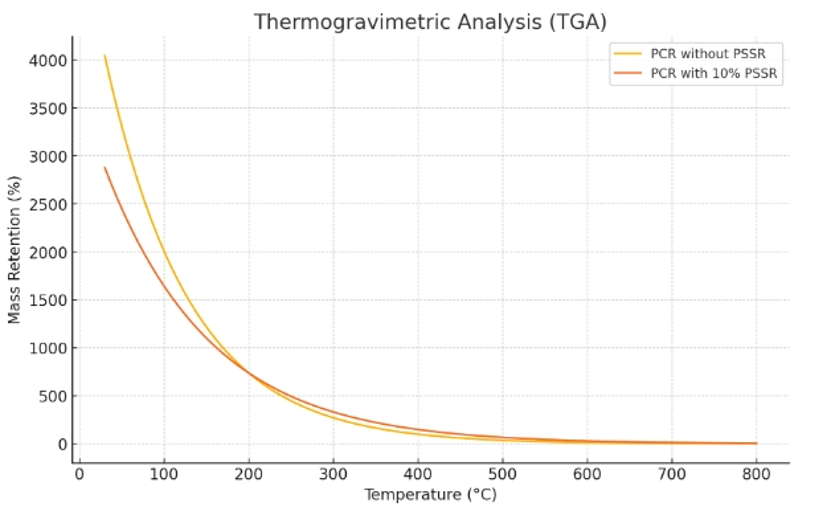

TGA Test Results:

| Temperature(°C) | 30 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|---|---|

| PCR (%) | 100 | 98 | 90 | 75 | 50 | 30 | 20 | 15 | 10 |

| PSSR (%) | 100 | 100 | 95 | 85 | 65 | 45 | 35 | 25 | 20 |

Neat PCR begins to undergo significant decomposition around 400°C, while PCR with 10% PSSR addition starts to show significant decomposition around 450°C. The mass retention rate of PCR with PSSR addition at high temperatures is significantly better than that of neat PCR, indicating that PSSR remarkably enhances the thermal stability of PCR.

Experiment Data

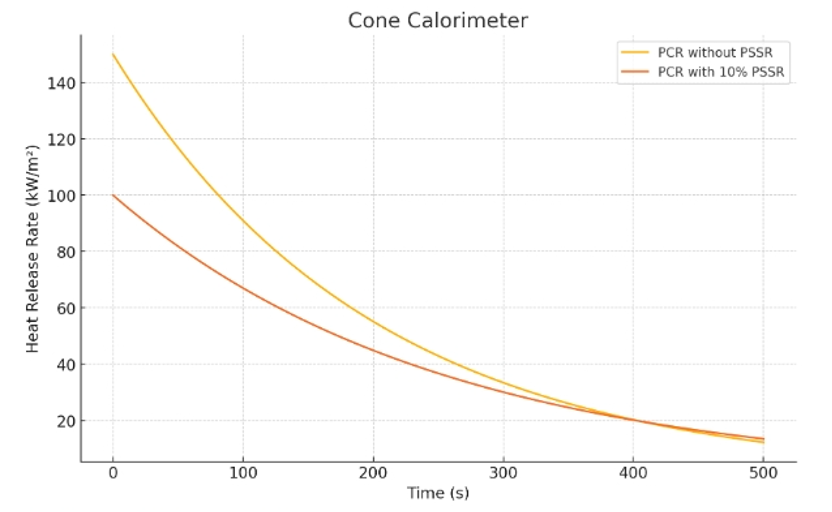

Cone Calorimeter Test Results:

| Time(s) | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HRR(kW/m²) | 0 | 50 | 100 | 120 | 130 | 120 | 100 | 80 | 60 | 40 | 20 |

| PSSR-HRR(kW/m²) | 0 | 30 | 60 | 80 | 90 | 80 | 70 | 50 | 30 | 20 | 10 |

Neat PCR exhibits a relatively high heat release rate (HRR), with the HRR increasing rapidly in the initial stage of combustion, while PCR with 10% PSSR addition shows a lower HRR and a slower burning rate. The incorporation of PSSR leads to a significant reduction in the HRR of PCR during the combustion process, indicating that PSSR effectively enhances the flame retardancy of PCR.