Halogen Free Solution:

Siloxane-Intumescent Nitrogenous Flame Retardant

SINFR

Environmentally

Friendly

Halogen free, release no harmful gases during combustion

effective

retardant

Incorporation of polysiloxane, IFR and nitrogen-based flame retardant enhances flame retardancy

material

safety

Excellent thermal stability and char-forming ability, significantly enhancing material safety

sustainable

Production

SINFR is suitable for large-scale production due to simple and cost-effective preparation method

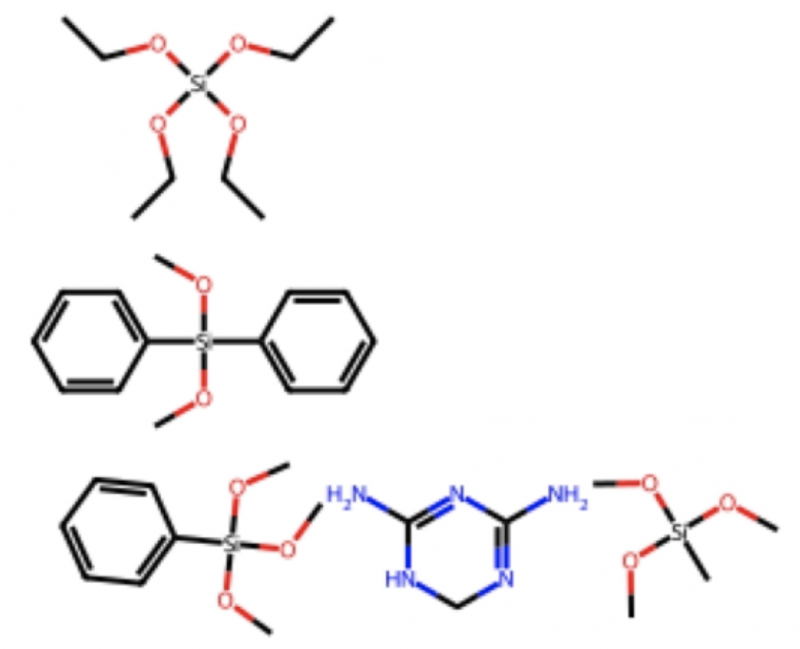

structure

SINFR is a composite flame retardant consisting of polysiloxane, an intumescent flame retardant (IFR), and a nitrogen-based flame retardant. The polysiloxane is synthesized by hydrolysis and condensation. The IFR is a composite of ammonium polyphosphate and kaolinite. The nitrogen-based flame retardant is a composite of melamine and formaldehyde.

SINFR 是由聚硅氧烷、膨胀型阻燃剂 (IFR) 和氮系阻燃剂组成的复合阻燃剂。聚硅氧烷通过水解缩合法合成,IFR 由聚磷酸铵和高岭土复合制成,氮系阻燃剂则采用三聚氰胺和甲醛复合制成。

Flame Retardant Mechanism

The Role of Polysiloxane:

- At high temperatures, it decomposes to form an insulating carbon layer with Si-C and Si-O-Si bonds, preventing the transfer of oxygen and heat to the substrate interior.

The Role of Intumescent Flame Retardant (IFR):

- Upon heating, it generates an expanding foam char layer that isolates the heat source and oxygen, reducing heat transfer.

The Role of Nitrogen-based Flame Retardant:

- By releasing inert gases, it dilutes the oxygen concentration in the combustion zone. Additionally, it forms a stable char layer, further enhancing the flame retardant effect.

More about Siloxane-Intumescent Nitrogenous Flame Retardant

The SINFR flame retardant is halogen-free, meeting environmental protection requirements. Its main components are non-toxic and non-polluting silicon-based compounds and nitrogen-based flame retardants. No harmful gases are released during combustion, making it environmentally friendly. The use of PCR materials contributes to resource recycling and aligns with the principles of sustainable development.

SINFR 阻燃剂不含卤素,符合环保要求。其主要成分为无毒无污染的硅基化合物和氮系阻燃剂,燃烧过程中不会释放有害气体,对环境友好。采用 PCR 材料,有助于资源循环利用,符合可持续发展的原则。

The SINFR flame retardant is suitable for PCR and its alloy materials, and can be widely applied in the fields of electronics, automotive, construction, and other areas requiring high flame retardancy. This flame retardant not only enhances the flame retardancy of the material, but also maintains good mechanical properties, making it suitable for various processing techniques.

SINFR 阻燃剂适用于PCR及其合金材料,可广泛应用于电子电器、汽车、建筑和其他需要高阻燃性能的领域。该阻燃剂不仅提高了材料的阻燃性能,还能保持良好的机械性能,适用于各种加工工艺。

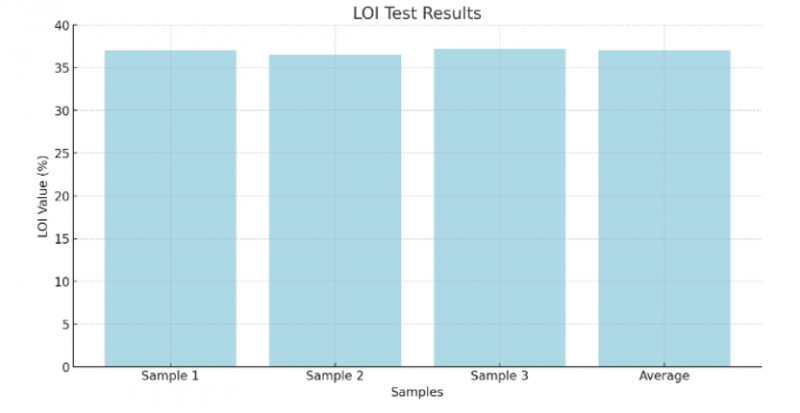

Experiment Data: LOI Test

LOI Test Results:

| Samples | LOI(%) |

|---|---|

| Sample 1 | 37 |

| Sample 2 | 36.5 |

| Sample 3 | 37.2 |

| Average | 37 |

The limiting oxygen index (LOI) value of PCR with SINFR is averaged 37%. The results demonstrate that with SINFR, the flame retardancy of the material is quite effective.

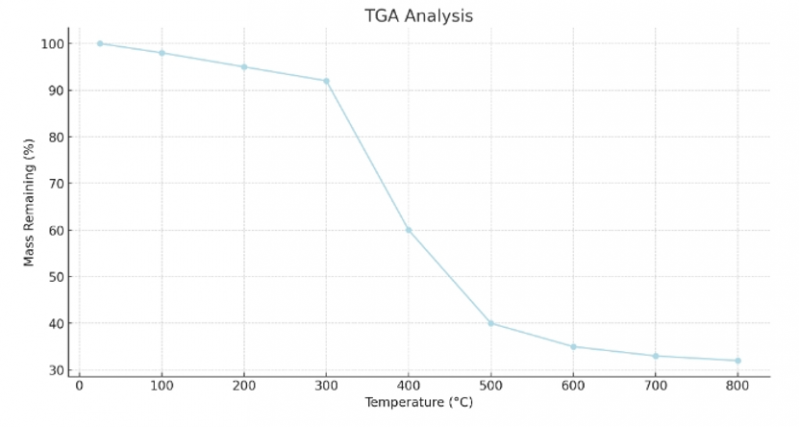

Experiment Data: TGA Test

TGA Test Results:

| Temperature(°C) | 25 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|---|---|

| SINFR (%) | 100 | 98 | 95 | 92 | 60 | 40 | 35 | 33 | 32 |

PCR with SINFR addition starts to show significant decomposition around 450°C, indicating that SINFR remarkably enhances the thermal stability of PCR.

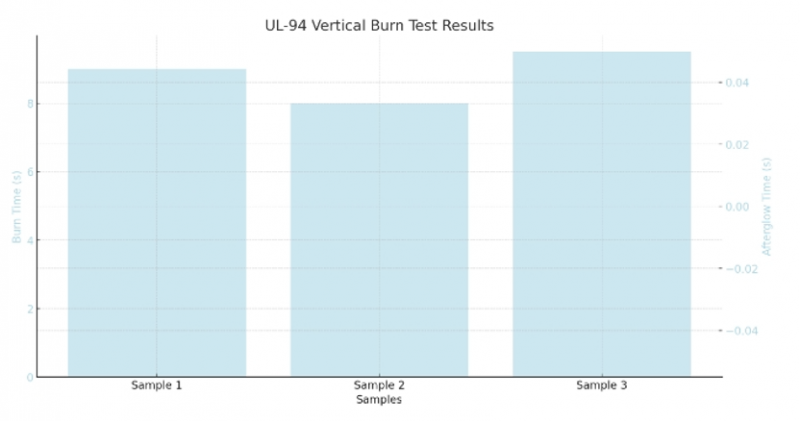

Experiment Data: UL94 Vertical Burn Test

UL94 Vertical Burn Test Results:

| Samples | Burning Time (s) | Glowing Time (s) | Rating |

|---|---|---|---|

| Sample 1 | 9 | 0 | V-0 |

| Sample 2 | 8 | 0 | V-0 |

| Sample 3 | 9.5 | 0 | V-0 |

3 three samples of PCR with SINFR have been rating V-0 level of retardancy, indicating SINFR effectively enhance the retardancy of PCR.

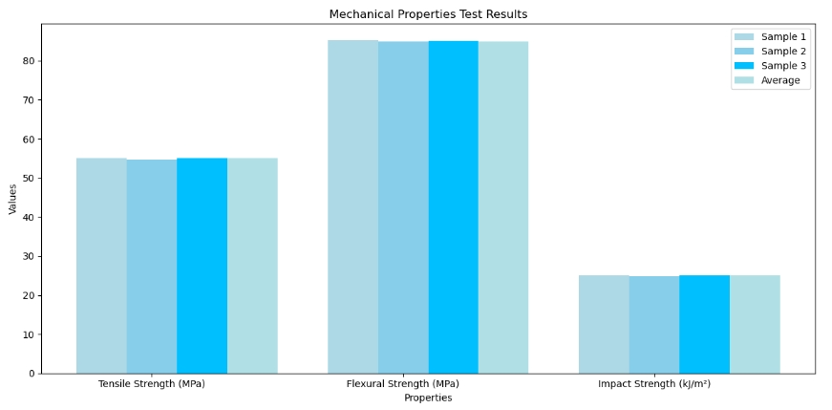

Experiment Data: Mechanical Properties Test

Mechanical Properties Test Results:

| Test Type | Sample 1 | Sample 2 | Sample 3 | Average |

|---|---|---|---|---|

| Tensile Strength (MPa) | 55.1 | 54.8 | 55.0 | 55.0 |

| Flexural Strength (MPa) | 85.2 | 84.9 | 85.1 | 85.0 |

| Impact Strength (kJ/m²) | 25.1 | 24.8 | 25.0 | 25.0 |